This is the simplest kind of work that we do, and mostly means cutting and drilling profiles,rebates,grooves and holes from above. Two dimensional male and female moulds can be machined with any offset for the component that is being laminated. Ribs for mould construction can be face drilled with dowel locaters for accurate assembly, which can be particularly useful if gluing up afterwards. We also offer the facility to glue up moulds for the customer if required. Much more complex three dimensional male and female moulds can also be machined, the main limitation for this really being the dimensional flexibility of the material to be laminated. (see our 3d page for more detail)

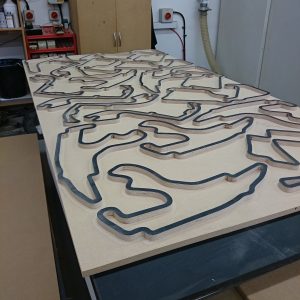

Flat, two dimensional templates can be machined, and for large assemblies, templates can be engraved with a reference or part number if required. Other useful techniques include jigsaw locaters where components need to be assembled side to side or end to end. We can also V-carve logos and text.